Enviro-Swine

using the Enviro-Barntm System

HEALTHY PEOPLE

Family:

Young children are especially sensitive to manure gas and have lower resistance to pathogen exposure Enviro-Barntm treats manure lagoons with oxygen and UV radiation to eliminate health issues for families living near livestock facilities.

Workers:

Humans working with livestock can also be sickened by odor and gas. Enviro-Barntm can provide a healthy and comfortable work places by quickly removing manure from the barn.

Neighbors:

Odor from untreated manure lagoons troves for miles. Lawsuits increasingly target live-stock. Judgments today reach millions of dollars. Lawsuit easily cost $100,000.oo just to defend.

Enviro-Barntm reduces the risk of lawsuits by cleaing up lagoons and barns to eliminate odors!

HEALTHY ANIMALS

…are raised in well designed, low-cost facilities with controlled environments to satisfy their natural wants and needs!

Does your operation suffer from any of these ill-advised recommendations?

Slatted Floors increase the cost of building and decreases production returns due to stress.

Pit Barns– reduce animal performance by 12% because of stress caused by noxious gasses.

Cold Barn– in insulation compromises temperature control. Condensation occurs resulting in a cold. damp and uncomfortable environment

Hot Barn lack of effective ways to cod animals causes huge losses in the production of meat or milk.

Pit Fans most often installed incorrectly, operating pit fans results in mixing noxious gasses and odors with the air in the bam.

Barn Curtains roll up or roll down curtains work best only with a mild breeze on a cool day. Improper use results in significant production losses.

Tunnel/Cross Ventilation -bringing in huge amounts of hot humid air and moving that air through the barn in an attempt to cool the animals, is a lesson in futility.

Evaporative Cooling uses more water than animals drink and a lot of energy for fans. Provides very little cooling and adds too much humidity in the barn.

Unit Heaters cause a conflict between heating and ventilation, radiant heat does not conflict

Solid Separators farmers now have two types of manure. liquid and solid, to spread on their fields.

“Sellers promote products that always make money for the seller, but often result in a loss, rather than a profit for the buyer.”

IMPROVE PROFITS 3 Ways

#1: ELIMINATE ODOR

Better Animal Performance. Healthier, Happier People. Lower Risk of Lawsuits. Carbon Credit: Available

#2: REDUCE COSTS

Lower Feed Bills. Reduce Heat and Ventilation. Cut Veterinary Bills. Reduce Maintenance. Avoid Equipment Wear-Out. Reduce Chores and Cleaning. Extend Building Life

#3: INCREASE PRODUCTION MORE FEED INTAKE

Better Feed Conversion. Faster Growth. Better Premiums.

…and the outcome is HEALTHY PROFITS

Upgrade Existing Facilities To Improve Swine Production Using Enviro-Barntm Elements!

Enviro-Barntm brings together best practices from around the world.

With 30 years experience and 5 years on-going research, The eXpert Company of Clintonville Wisconsin has completely redesigned the old fashioned barn to solve urgent industry needs for livestock feed savings, performance efficiency and better animal health. Enviro-Barntm enables the promise of high performance genetics and feed rations.

Enviro-Barntm odor-free facilities offer 15% faster gain using 25% less feed.

Besides improved health and feed savings, Enviro-Barntm systems transform manure into odor-free, crop-ready, fixed-nitrogen fertilizer. This true-liquid fertilizer can be crop applied as foliar feeding, whenever crops need nutrients most. Timely crop-ready fertilizer applications can deliver 20-40 more bushels of corn per acre — and nutrients don’t run off.

Remodeling

Using Enviro-Barntm elements to remodel existing facilities, producers gain profits without building a new barn. Animals grow faster on less feed! As a bonus, neighbors, family and workers no longer experience stinky ponds and odor-filled barns.

EXAMPLE: A small 600 pig finisher barn!

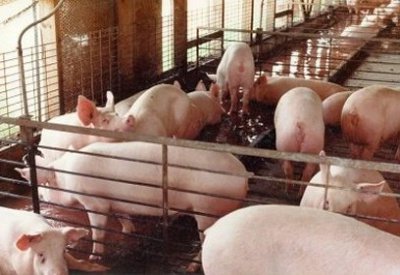

Pictures on the following page show a finisher facility renovated nearly 20 years ago. The farmer was tired of slow growing pigs in a stinky pit barn. Renovation installed Flo-Thru gutters on top of the slatted floor. An aerobic pond provided “Safe Water” for recycling. Using Enviro-Barntm core elements avoids in-barn odor and noxious gasses that slow growth and reduce feed conversion. Pigs finish 15 days early and 20 lbs heavier on 25% less ration. With Enviro-Barntm, both feed and fresh water usage are reduced. Lowering costs by more than $20.00 per pig means payback in less than one year. As feed prices rise, profits from feed savings will continue to increase.

This barn upgrade uses only two elements from the Enviro-Barn’ swine improvement system.

Remodel – using Flo- Thru gutters.

Pigs enjoy the beach too!

Notice the clean pigs and the clean floors. Manure is no longer stored under the floor in a pit. By nature, pigs dung in safe cold, damp areas along the sides of their pens.

Look in your barns. Where does the dung pile up? Pigs see these places as safe spots for dunging or too cold for comfort when resting?

Look in your barns. Where does the dung pile up? Pigs see these places as safe spots for dunging or too cold for comfort when resting?

In these pictures, water color indicates partial lagoon transformation. Today, energy efficient Toroidal circulation supports complete lagoon transformation into “safe water” for recycling and barn cleaning!

University Studies from Cornell, Perdue and Ames in early 1970’s show slatted floors reduced ADG in pigs 12%- 15%. Further studies of in the 1980s verified ammonia at 50ppm reduced ADG by 12%, at 100ppm ADG fell by 30%. Pit barns today easily produce 50-100ppm of ammonia. Say again, why don’t pigs grow well?

Isn’t it time to change your old barn and make significantly more profit from doing things in an odor-free and more environmentally friendly manner?